Renovating existing residential buildings to incorporate Renewable Energy Sources (RESs) has long been hailed as a crucial step towards sustainability. However, one of the major hurdles faced by renovation projects is the laborious and time-consuming process of building modeling, designing and adjusting the layout of prefabricated modules. ENSNARE introduces three innovative solutions aimed at streamlining the integration of prefabricated modules with RESs, making energy-efficient renovations more feasible and efficient than ever before.

- Semi-Automated building modeling

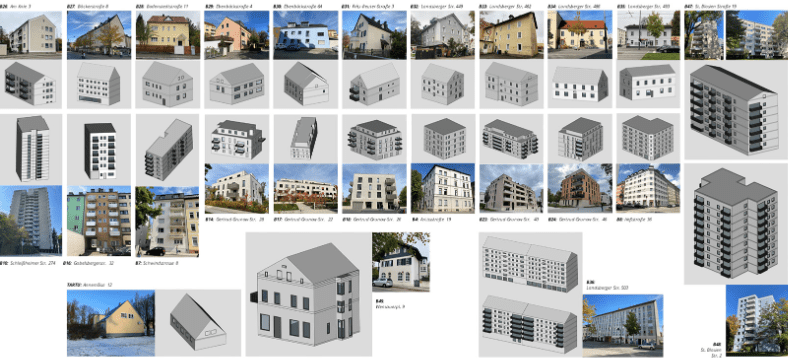

The first step before proceeding to any digital workflow is to model the existing conditions since old buildings rarely have any digital representation. To manually create it could be time-consuming and require basic modeling skills. In addition, there is an increasing availability of open data sources and digital formats concerning the building stock, although in different levels of detail, quality, availability, or reliability. In ENSNARE we developed a flexible workflow for drastically reducing the time and cost of the IFC model generation process of an existing building for façade renovation purposes.

- Semi- Automated Drafting of Optimized Layouts

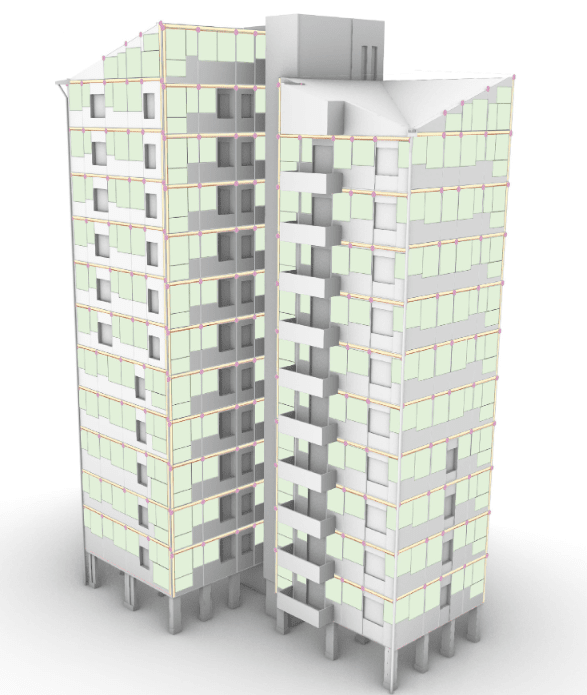

Traditionally, drafting the layout of prefabricated modules and allocating solar panels has been a manual, error-prone process, consuming valuable time and resources. ENSNARE revolutionizes this aspect with the introduction of an automated drafting tool. This tool generates optimized layouts of prefabricated facade modules seamlessly integrated with solar panels (see Figure 1). The result? Highly efficient and visually appealing module layouts, complete with detailed visual plots, JSON files containing module coordinates, and Excel sheets for accurate cost estimation. This empowers stakeholders to make informed decisions, swiftly and confidently, significantly expediting the renovation process.

- Automated Adjustment of Layouts

ENSNARE addresses another critical challenge: the need for dynamic adjustment of module layouts based on real-time measurement data. Traditional manual adjustments are not only time-consuming but also prone to inconsistencies and inaccuracies, leading to delays and cost overruns. To combat this, we pioneer algorithms capable of dynamically reconfiguring module layouts in response to real-time measurement data obtained during site visits. By seamlessly integrating measurement data into the existing building model, these algorithms ensure precise and adaptive adjustment of the module layout, minimizing the need for manual intervention and enhancing the overall accuracy and efficiency of renovation projects.

The efficacy of ENSNARE’s solutions was rigorously tested across multiple residential buildings (pilots), yielding promising results. Application of the automated drafting and adjustment tools resulted in substantial time savings compared to traditional manual methods. What used to consume hundreds of hours in manual layout definition now takes minutes with the automated tools, significantly expediting the renovation process. Stakeholders, including building owners, promoters, and engineers, lauded the tools for their ability to facilitate informed decision-making and enhance the economic viability and energy efficiency of renovation projects.

ENSNARE takes a step forward in the integration of prefabricated modules with RESs in residential buildings. By automating the drafting and adjustment of module layouts, we address not only the time-consuming nature of renovation projects but also enhance their accuracy and efficiency.